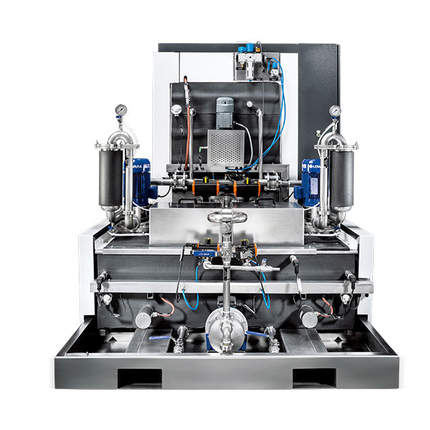

EcoCcube – Effective spray cleaning for a variety of applications

The EcoCcube was conceived for the qualitatively effective, aqueous spray cleaning of machined and non-machined individual parts with diverse geometries. The very compact dimensions of the system meet the demand for more efficient cleaning technology when space is limited. This also makes it ideal for use as a local or stand-alone solution for intermediate cleaning, as well as for simpler cleaning tasks.

Work pieces soiled with oil and/or emulsion can be cleaned as individual or bulk components. The system works with a high circulating flow rate, both when cleaning and when rinsing. The cleaning effect of the medium used is supported through the rotation of the parts in the work chamber. The parts are dried by means of high-temperature air circulation without loss of vapor. This guarantees optimal cleaning results at a high throughput.

Equipment and process

- 2-stage spray unit (Washing /Rinsing) with hot-air drying

- User-friendly front-loading system with integrated manual loading device

- All-round spray system

- For bulk material in baskets or for rack goods

- Basket rotation on a horizontal axis

Equipment features

- Oil skimmer

- Full-stream filtration

- Floor tray

- Discharge pump

- Programmable control system with 10 programs

Advantages

- Efficient cleaning: effective cleaning and rinsing at short cycle times and long bath lives

- Small footprint: compact system design ready for connection

- High cleaning quality: optimized cleaning results thanks to shifted parts, also for damage sensitive parts

- Modern system design with integrated, intuitive HMI control panel

Back