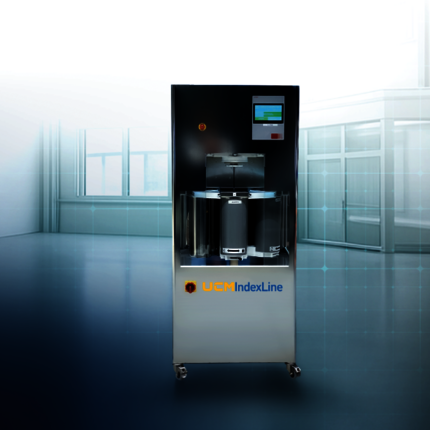

UCMIndexLine – Precision Cleaning for Complex Small Parts

The compact UCMIndexLine rotary indexing system combines six flexible cleaning and rinsing stations (with and without ultrasound) for complete aqueous precision cleaning processes. It is specially designed for the smallest and complex components and allows any process sequence.

The UCMIndexLine is a very compact rotary indexing system with six cleaning stations for precision cleaning on an aqueous basis. With the integrated cleaning and rinsing stations, with and without ultrasound, almost all processes can be mapped. Thus, any process sequence as well as any number of process sequences can be represented. The system is especially designed for very small and complex components.

Machine concept

- Designed for cleaning small mechanical parts

- Ultrasound technology with interchangeable vessels

- Cleaning under vacuum with Pulsated Pressure Cleaning (PPC)

- Spinning of the basket with programmable speed

- Automatic control of temperature and liquid level

- Freely programmable cycle times

- Up to 1,000 programs with up to 30 phases storable

- CU-4000 control

- System operation via 6,5“ LCD touch screen

- Extremely compact system (< 1m²)

- Maintenance friendly design

- Process registration for statistics, history and quality control available (option)

Fields of application

- Medical technology e.g. for implants, surgical tools, medical instruments, dental technology, 3D printing, cleaning of capillaries and boreholes

- Thin film coating (PVC/CVD) e.g. for tools, automotive parts, fittings

- Precision optics e.g. for micro optics, lenses, mirrors, prisms, masks

- Precision mechanics / precision parts e.g. for aircraft, automotive parts, watches, jewelry

Features and benefits

- Designed for cleaning small mechanical parts: Ultrasound technology with interchangeable vessels

- Vacuum-based cleaning: Pulsated Pressure Cleaning (PPC) as an option

- Maximum process flexibility: up to 1,000 programs with up to 30 phases storable

- Automated quality control and documentation: continuous monitoring of temperature and liquid level, as well as optional process recording for statistics, history, and verification purposes

- Compact, maintenance-friendly design: less than 1 m² footprint, easily accessible maintenance areas

Back